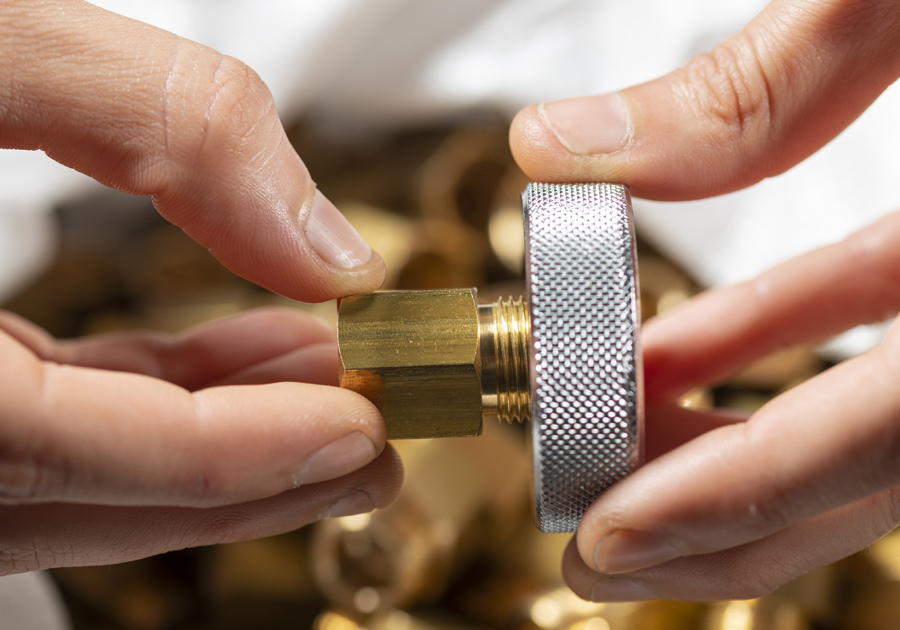

The secondary machining department is our strongest point,

where we create the finished product with boring and threading

– transfer type machines - milling, broaching, bendingand

last, but by no means least, rolling, which is the very core

of the department.

According to the specific needs

of the customer, all products can be subjected to

galvanisation, nickel-plating, burnishing, and Geomet®. We

have recently introduced a tumbling system that allows us to

remove machining burrs and polish any type of product. We make

parts for different industrial uses, from mechanics to

electronics, hydraulics, oil hydraulics, automotive and

furniture.

Our production area is divided into two departments: one to manufacture bespokesmall-turned parts in metal–using CNC machines and traditional mechanical lathes –and the other for secondary machining operations. The production department contains 11 CNC lathes, with fixed or sliding head, to guarantee quality, precision, and flexibility. The use of dedicated management software means seamless interface with the company network and perfect remote control of business activities. Our high-level CNC technology is flanked by 20 traditional mechanical lathes that, although used to manufacture simpler parts, allow us to produce large batches while remaining extremely competitive in terms of price. Our small mechanical parts are subject to checks using suitable control instruments both during production and on the finished product atthe end of the cycle. We can also provide PPAP documents to guarantee the quality of our products.

Machine Park

11 CNC MACHINES

20 LATHES

Bar Passage

Ø3 - Ø65

Raw Materials

- Free-cutting steel

- Steels for quenching and tempering

- Case-hardening steels

- Martensitic and Austenitic

- Stainless steel

- Alluminium

- Brass

- Copper

- Bronze

- Delrin®

Sectors

- Mechanics

- Elctronics

- Hydraulics

- Oil Hydraulics

- Automotive

- Furnishings

- Fashion